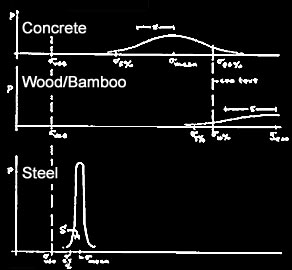

We know that the mechanical properties of timber are changing with the age,

date of harvest, degree of humidity and climate, soil conditions, location,

etc. Furthermore, there are differences over the length of the trunk or

cross-section, and also, whether the loads are parallel or perpendicular

to the direction of the

fibers.

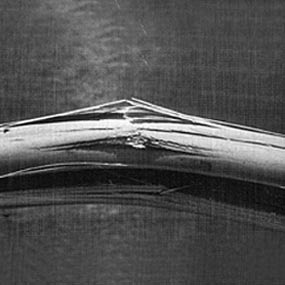

The deviation of characteristic strength values is almost even bigger in

bamboo, showing very different density in the cane wall section and also

its diaphragms.